Available with special Design according to

the customer request Delivery length upon

customer request. Other color coding is

available according to the customer request

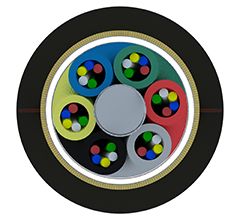

CONSTRUCTION:

|

Specification |

Recommended |

|||

|

Standard |

IEC 794-1, ITU-T G652D, IEEE P1222 |

|||

|

Construction |

||||

|

Design Type |

1-layer cable core / Laminated water blocking tape /1jacket |

|||

|

Number of Fiber |

4 to 144 |

|||

|

Optical Fiber Type |

Single Mode LWP |

|||

|

Central strength Member |

Material |

FRP |

||

|

Diameter |

Nom. 2.5mm that will bind to 2.7mm with water swell able yarn |

|||

|

Loose Tube

|

Tube Material |

PBT |

||

|

Filling Compound |

Thixotropic jelly compound |

|||

|

Assembly |

6 optical fibers will have placed loosely into a jelly-filled thermoplastic tube |

|||

|

Diameter |

Nom. 2.4 mm |

|||

|

Number of Fibers |

6 or 12 |

|||

|

Color |

|

1)white 2) red 3) Green 4) blue5) yellow6) black 7) brown 8) violet 9) orange 10) pink 11) gray 12) natural |

||

|

Stranding |

loose tube(s) and filler(s) will be stranded around the strength member and will wrapped with a layer of Water blocking tape and Aramid Yarns |

|||

|

Core Wrapping |

Water blocking tape |

|||

|

Inner Sheath (Optional) |

Material |

- |

||

|

Thickness |

- |

|||

|

Ripcord |

2 opposite Ripcords under the jacket |

|||

|

Reinforcement |

Aramid yarns |

|||

|

Outer Sheath |

Material |

High Density polyethylene colored black & Anti-tracking |

||

|

Thickness |

Nom. 2.0 mm |

|||

|

Cable Diameter |

Nom. 12.5 to 17.5 mm |

|||

|

Cable Weight |

Nom. 0.121 to 250 kg/m |

|||

PERFORMANCE:

|

Specification |

Recommended |

|||

|

Mechanical Characteristics |

||||

|

Tensile Strength |

According to costumer request |

|||

|

Compression |

220 N/100mm |

|||

|

Min. Bending Radius |

Installation |

15*D (Cable Diameter) |

||

|

Operation |

20*D (Cable Diameter) |

|||

|

Environmental Characteristics |

||||

|

Temperature |

Installation |

-30°C to +70 °C |

||

|

Operation |

-40°C to +80 °C |

|||

DESCRIPTION:

More calculation necessaries:

The information about environmental features (external loads) like Ice load, wind load …

The vertical distance from the electrical power lines.

Sag (%)

Effective span length